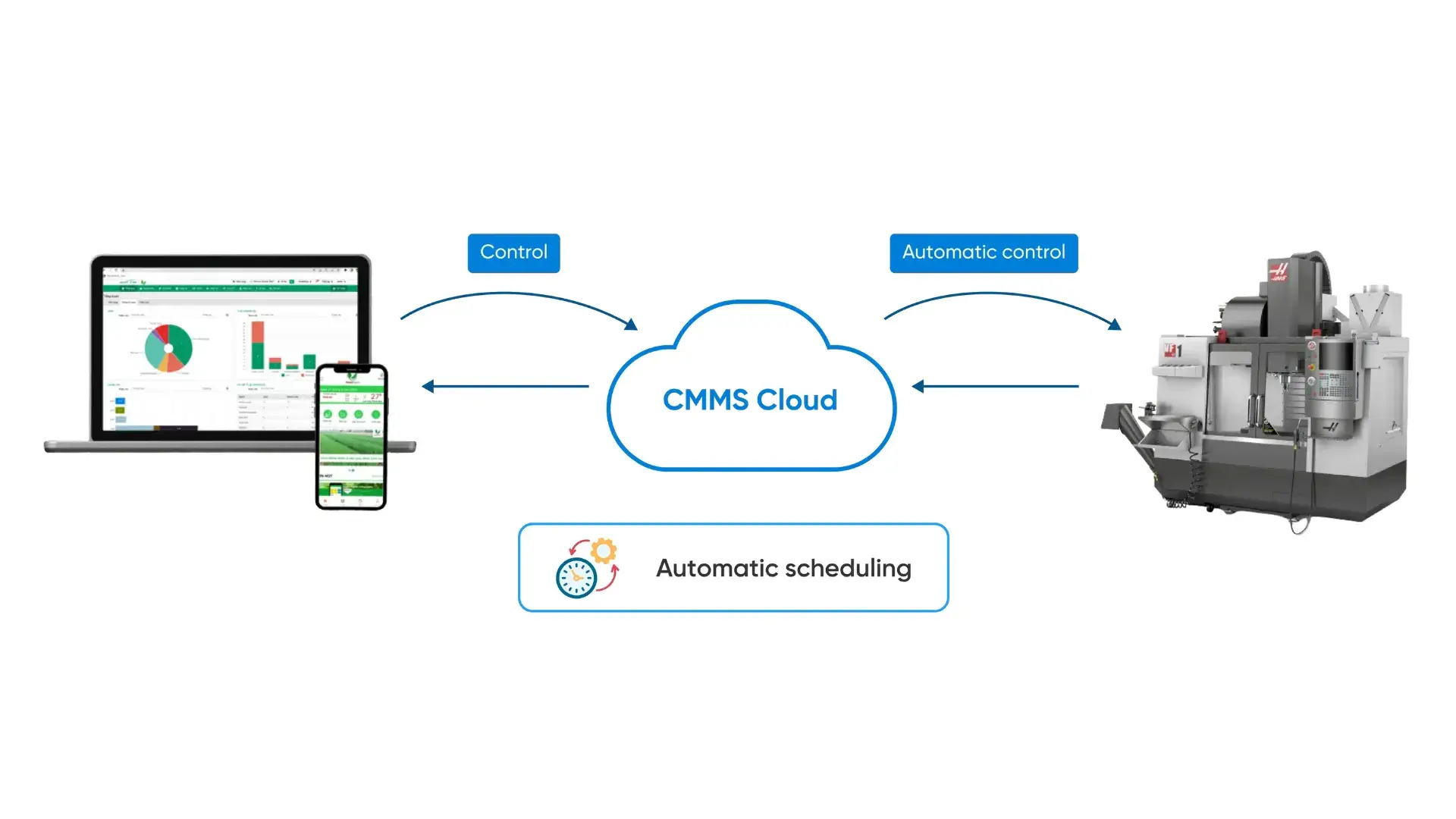

CMMS Overview

Computerized Maintenance Management System (CMMS) is a system to help managing and monitoring the assets and equipment of the enterprise in a systematic way.

Reduce the cost of manual management time and labor.

Increase maintenance efficiency & work efficiency of the technical team, as well as avoiding unexpected damage and loss.