Case Study

Project Highlights

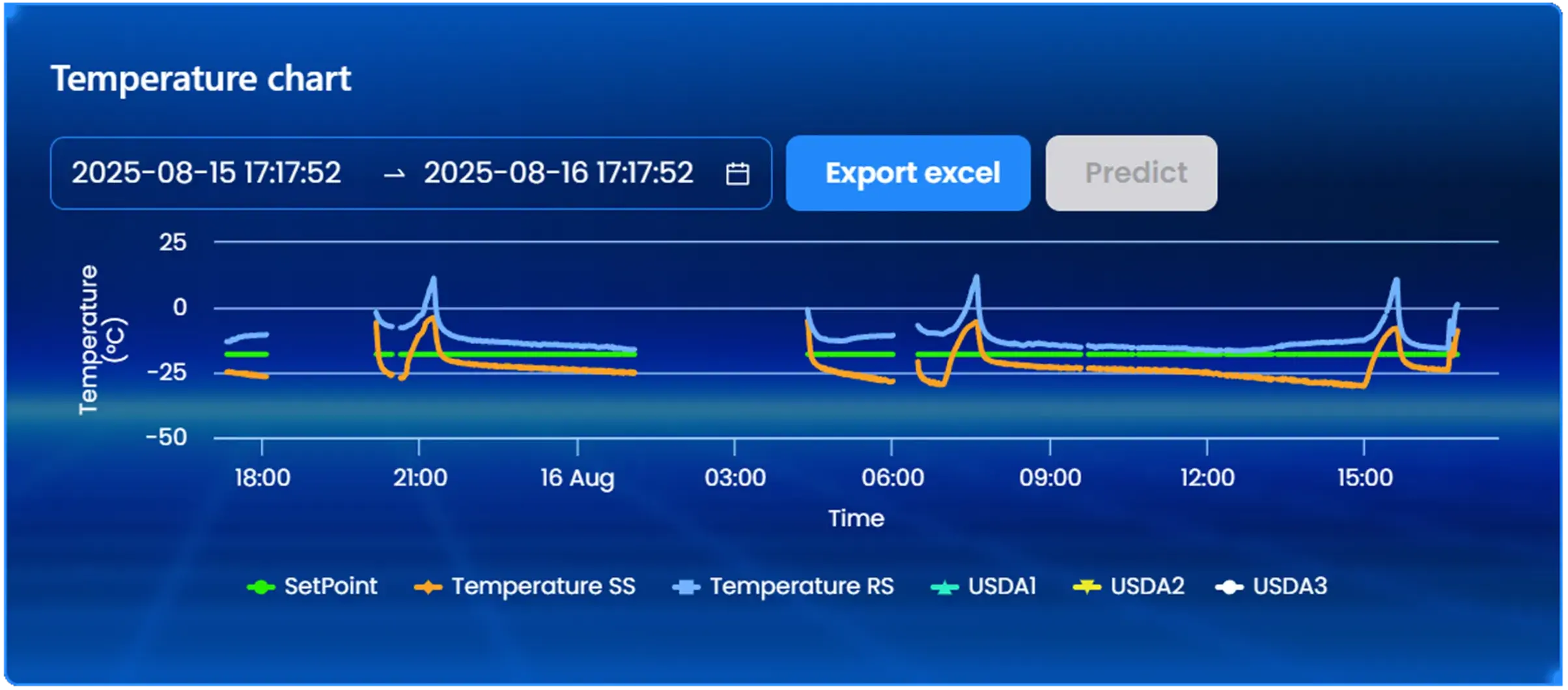

- IoT-Driven Environmental Control: Implement an IoT solution to continuously monitor and manage temperature and humidity levels within containers.

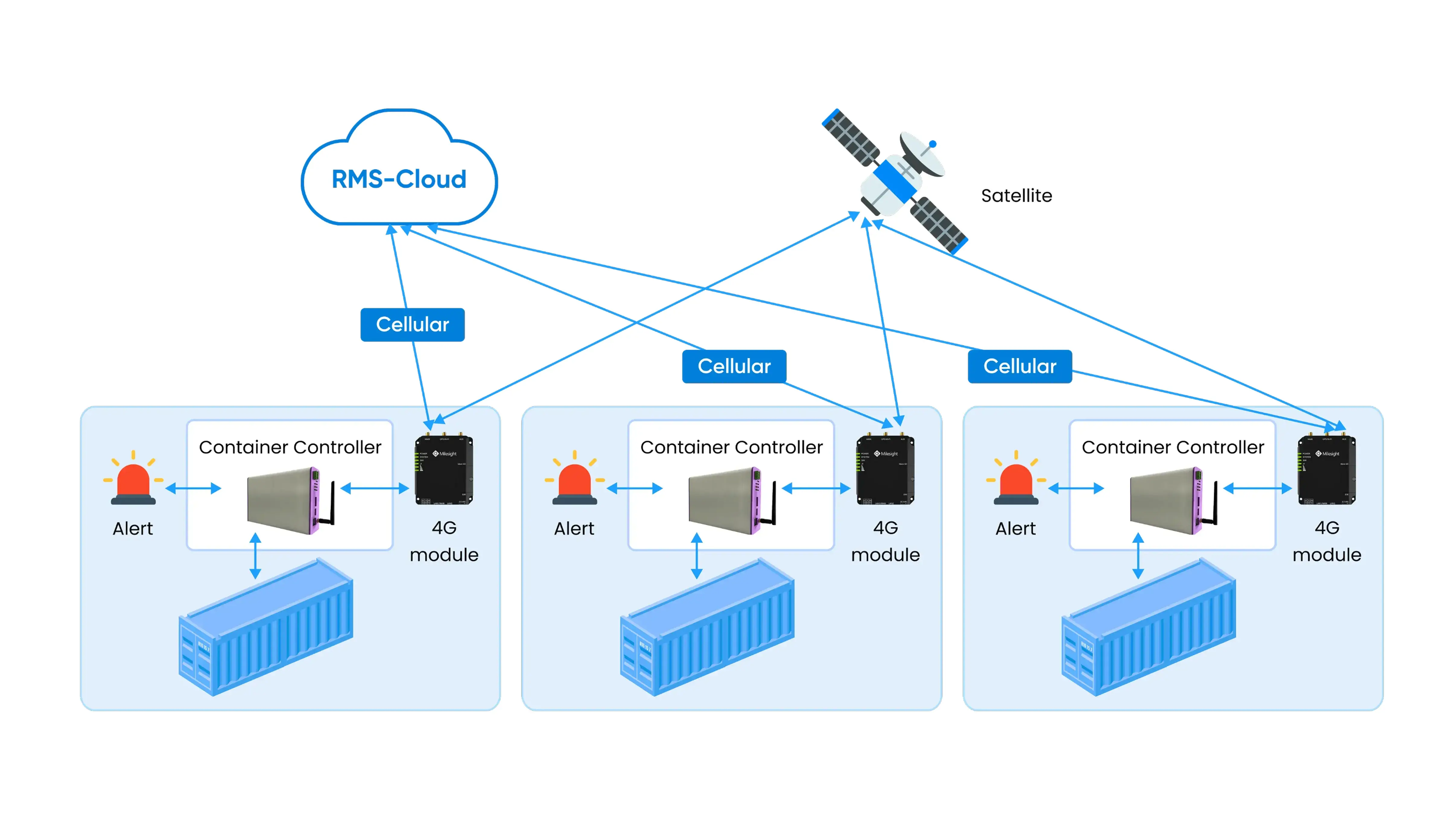

- Real-Time Data Transmission: Utilize 4G connectivity for instant access to container conditions and locations from anywhere.

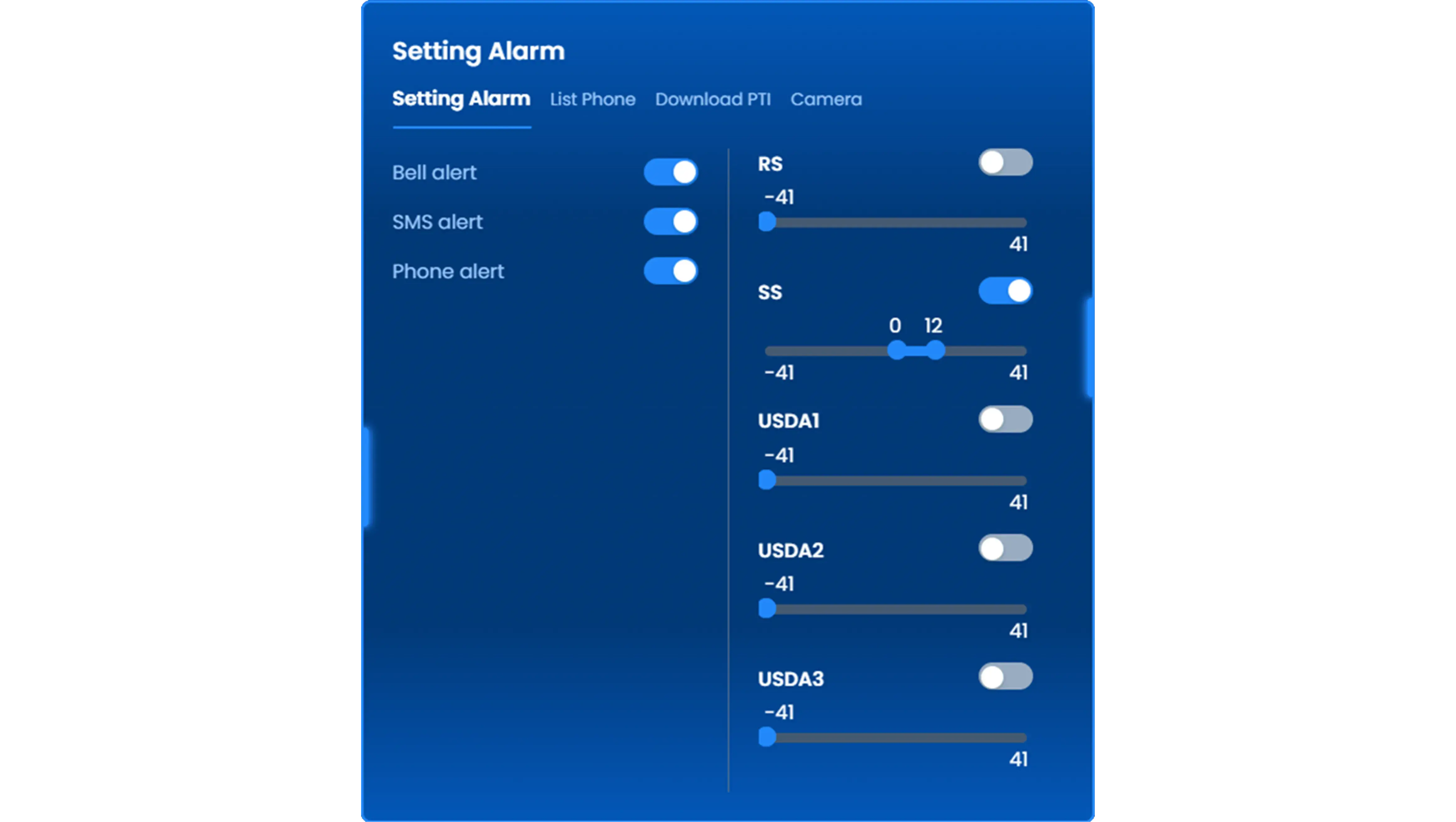

- Proactive Anomaly Alerts: Establish automated alerts for temperature and humidity issues, enabling prompt intervention to protect cargo integrity.

Problem Statement

- Lacking Temperature and Humidity Control: Limited control over internal container conditions might cause damage to goods during transport.

- Delayed Issue Detection: The client struggled to detect and address abnormalities and problems arising within the containers promptly, which increased the risk of further complications and losses.

- High Labor and Time Costs: Manual monitoring and controlling container temperatures required significant labor and time, increasing operational expenses.

Solutions

- IoT Application: Leverage IoT technology to manage temperature and humidity within the containers.

- Wireless Connectivity: Support wireless connection via 4G mobile networks, enabling seamless data transmission for monitoring anytime, anywhere.

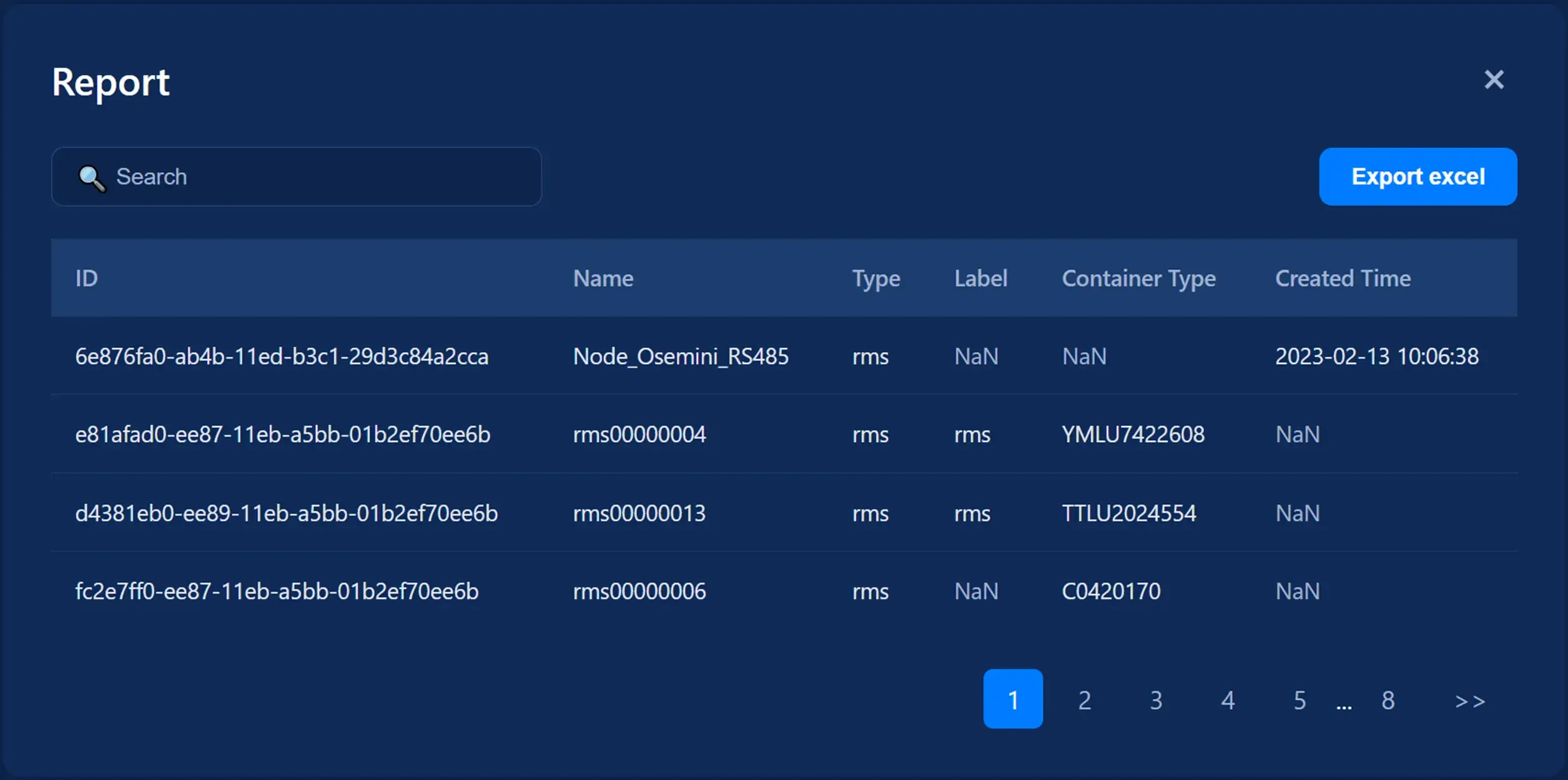

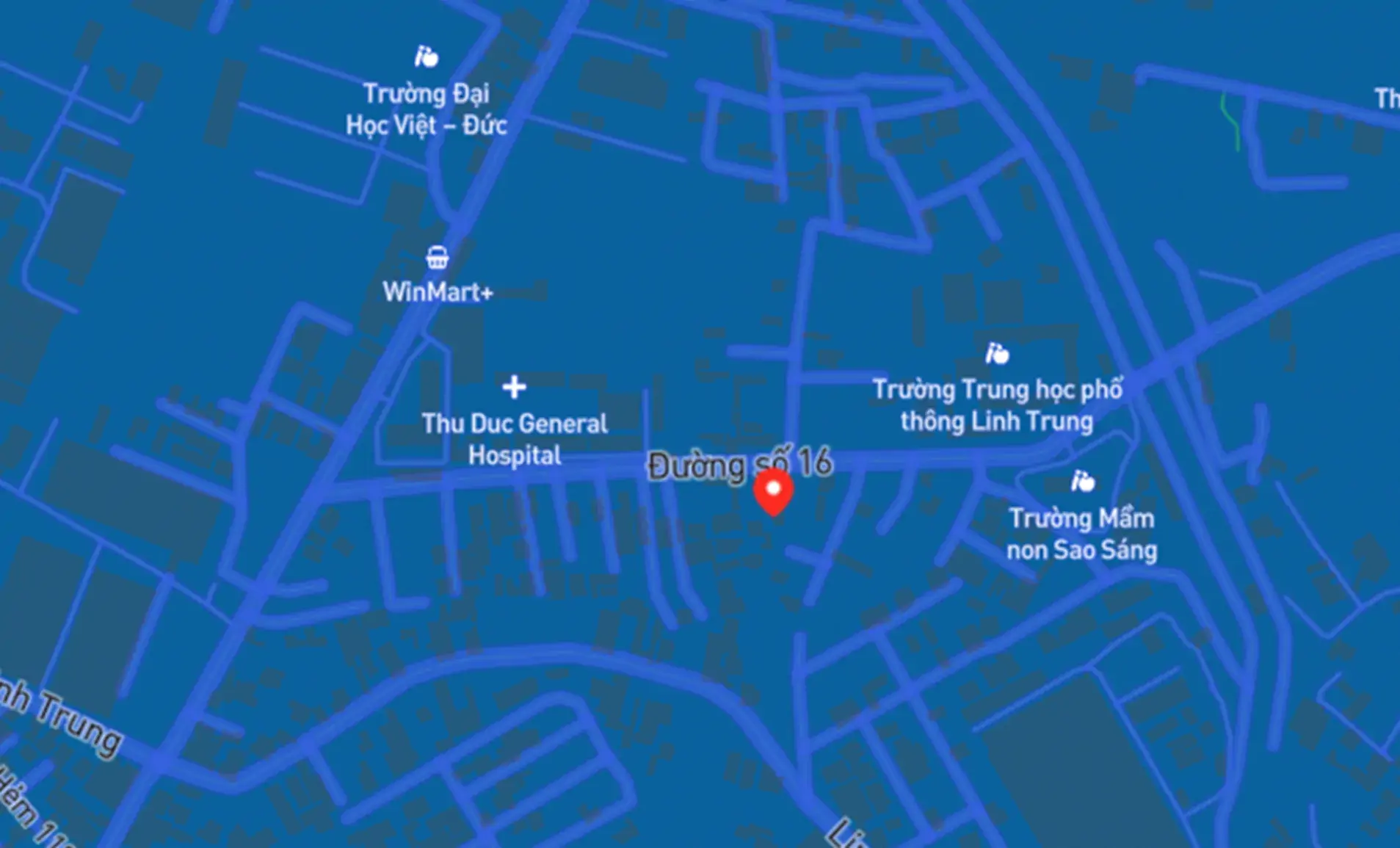

- Digital Map Integration: Use a digital map interface to manage and track container locations, and improve operational oversight.