Smart Computerized Maintenance Management System (SCMMS)

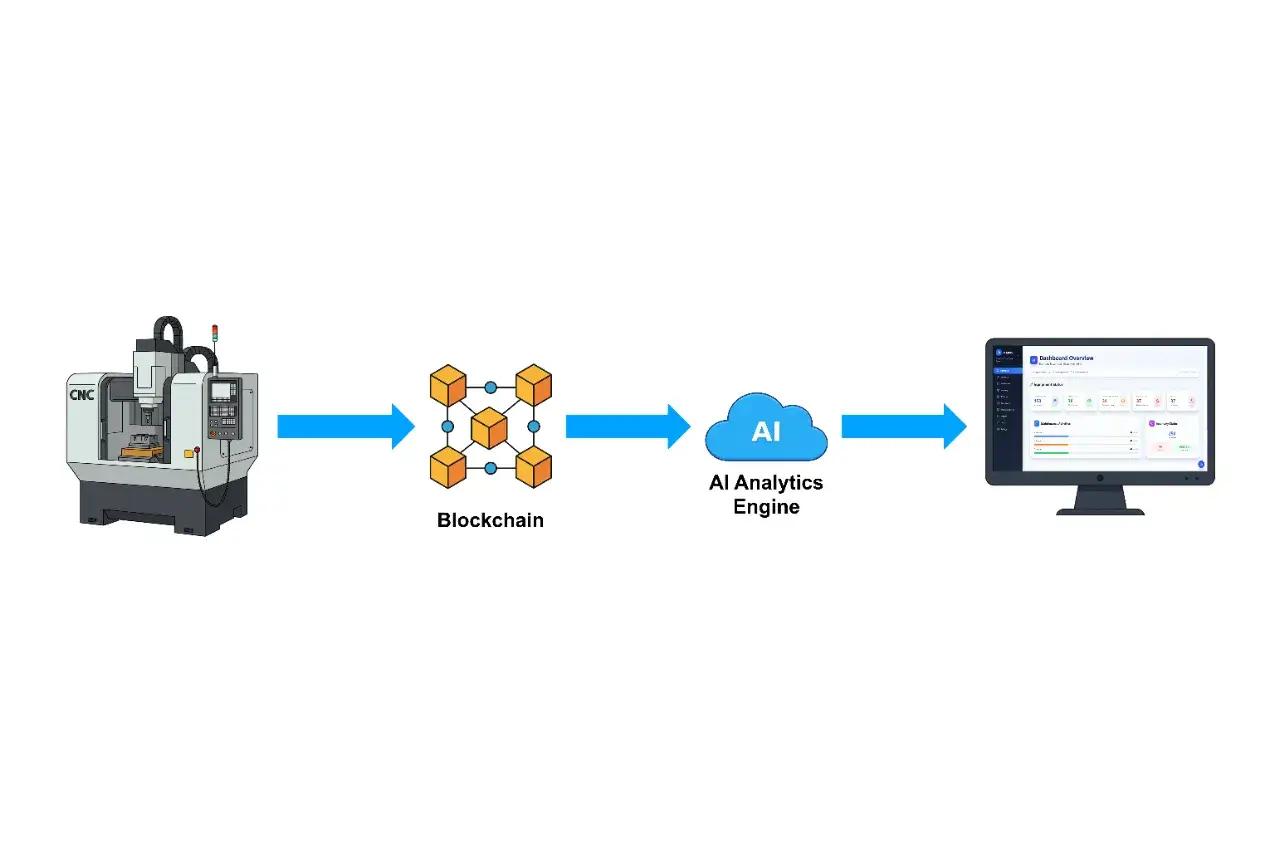

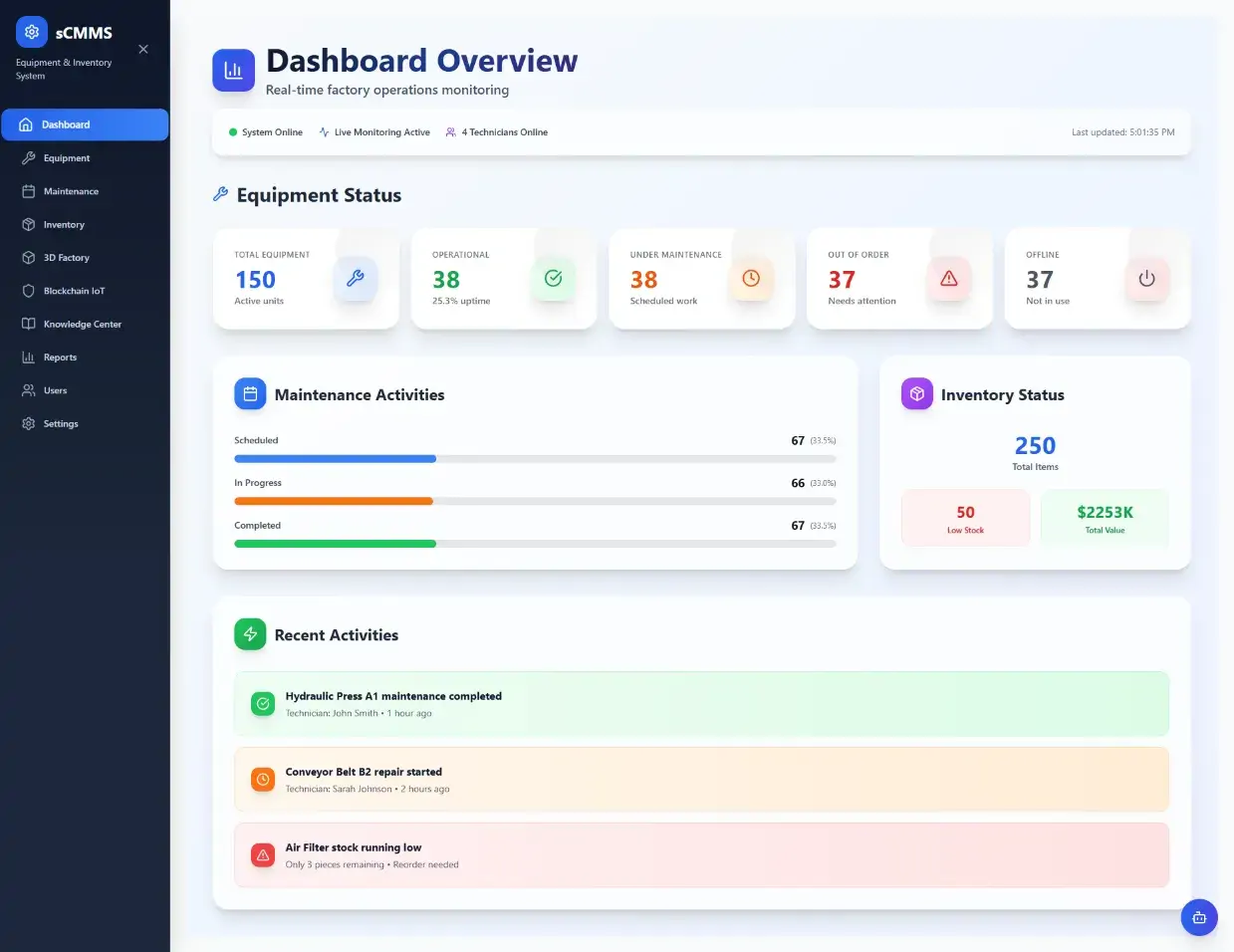

Smart Computerized Maintenance Management System (SCMMS) is an innovative, AI-powered platform designed to provide a centralized command center for all manufacturing operations, enabling managers to prevent costly failures, optimize processes, and drive production efficiency.