Case Study

Project Highlights

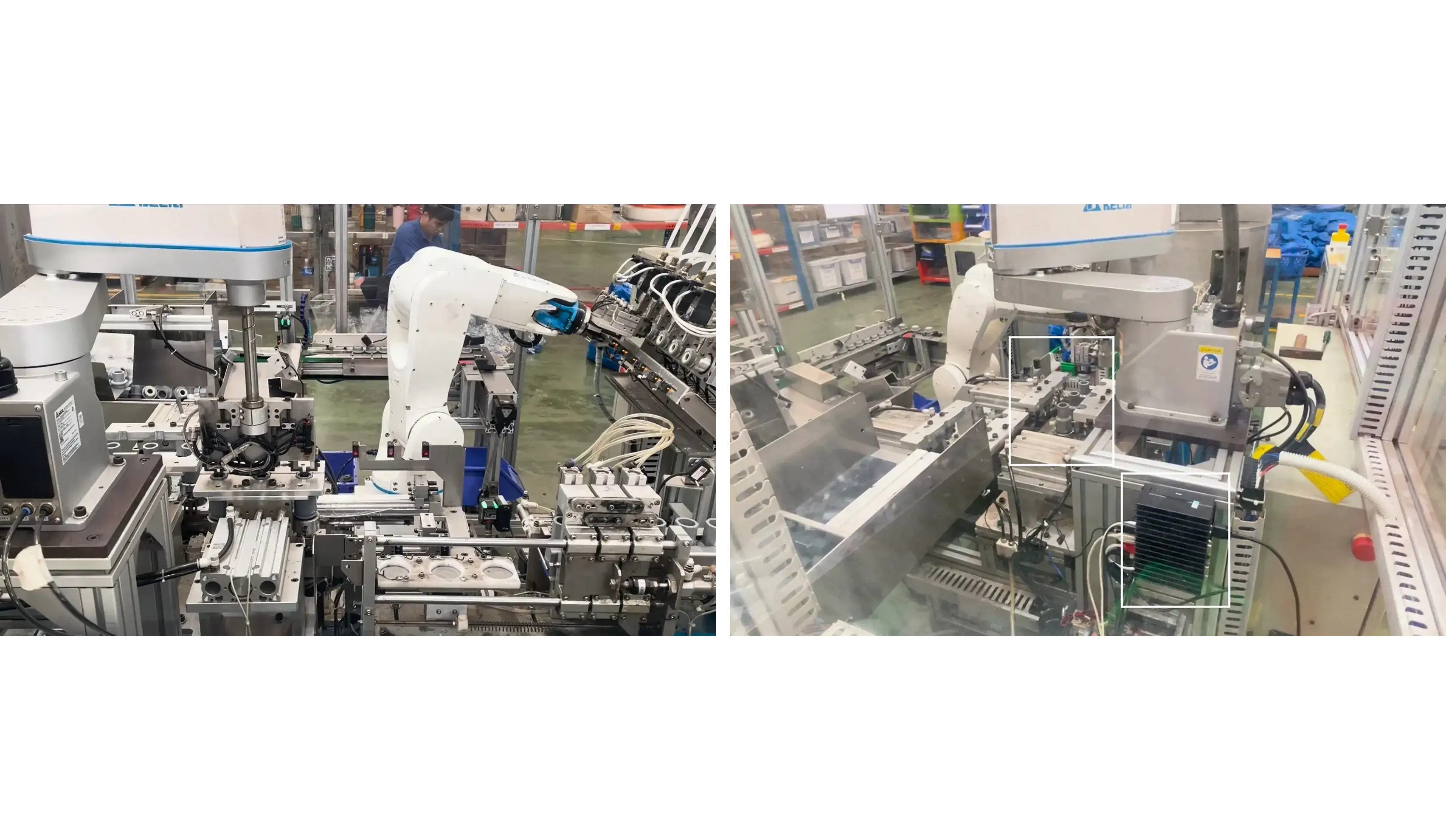

TMA Solutions proposes a cutting-edge Predictive Maintenance solution powered by Generative AI (ChatGPT 4.0) to improve the health monitoring of machines and devices in factory operations. By combining AI-driven data analysis with natural language generation, the system delivers actionable maintenance insights in a conversational format easily understood by operators and technicians.

This solution aims to increase equipment reliability, extend machine lifespan, and reduce unplanned downtime, helping manufacturers operate more efficiently.

Problem Statement

- Complex sensor data: Traditional systems struggle to make sense of high-volume machine logs and sensor outputs.

- Limited interpretability: Maintenance recommendations are often too technical or fragmented for quick decision-making on the shop floor.

- Reactive maintenance: Equipment is often fixed after failure, resulting in production delays and higher costs.

Solutions

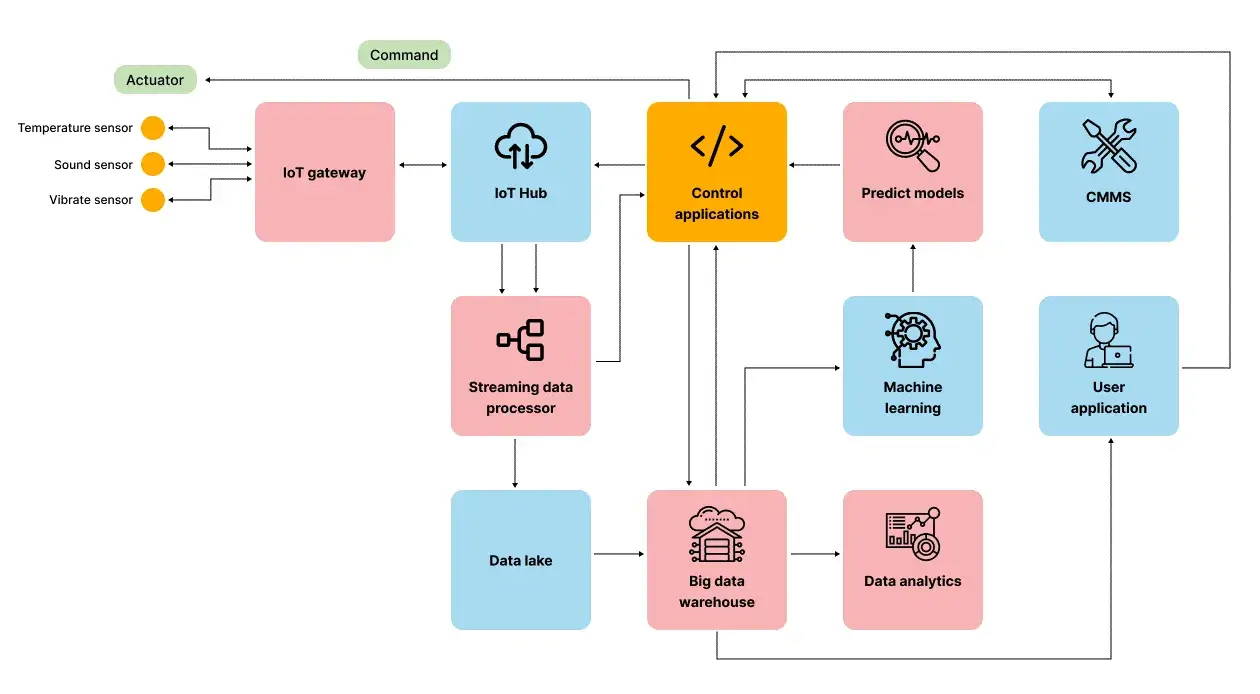

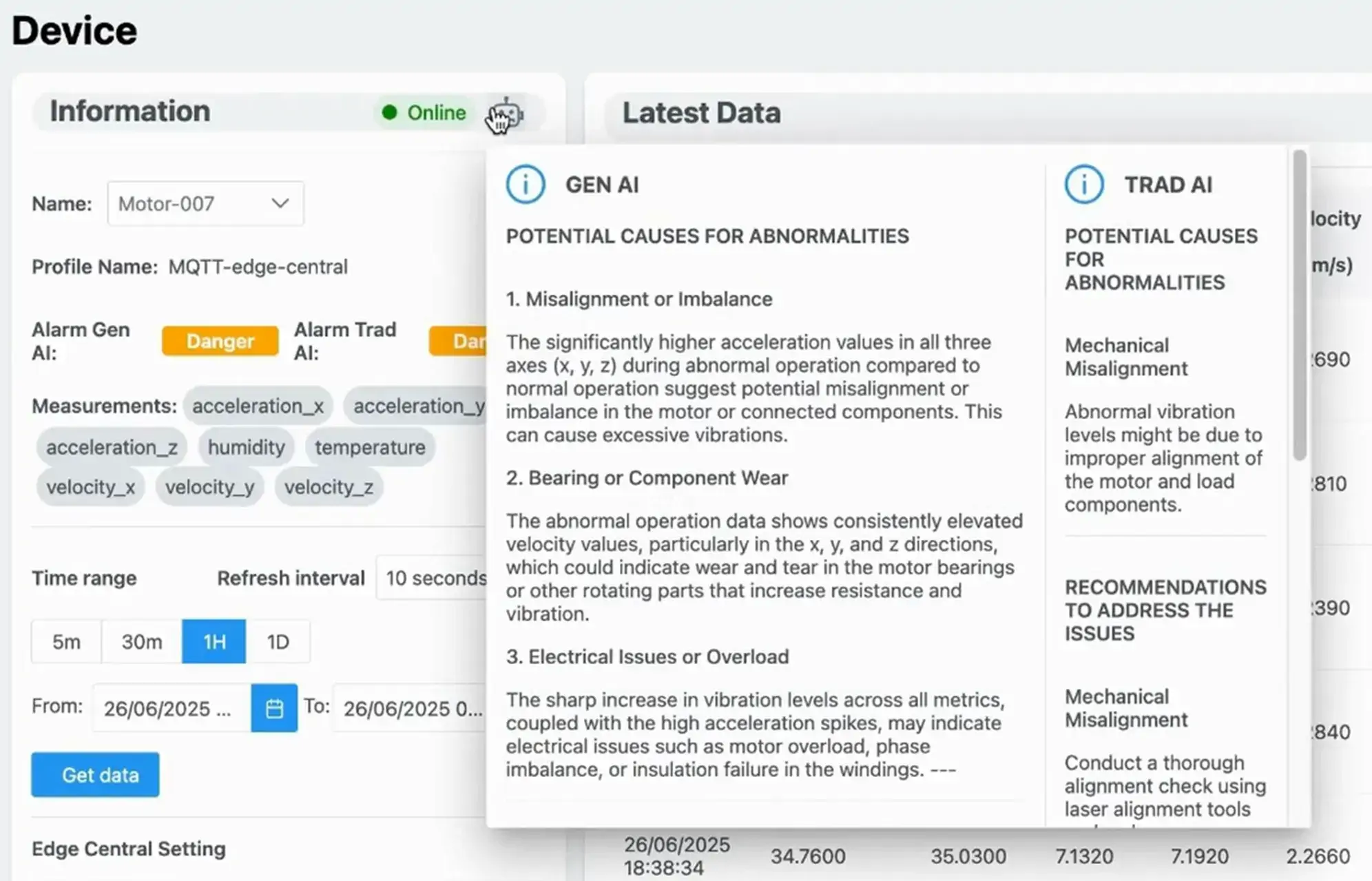

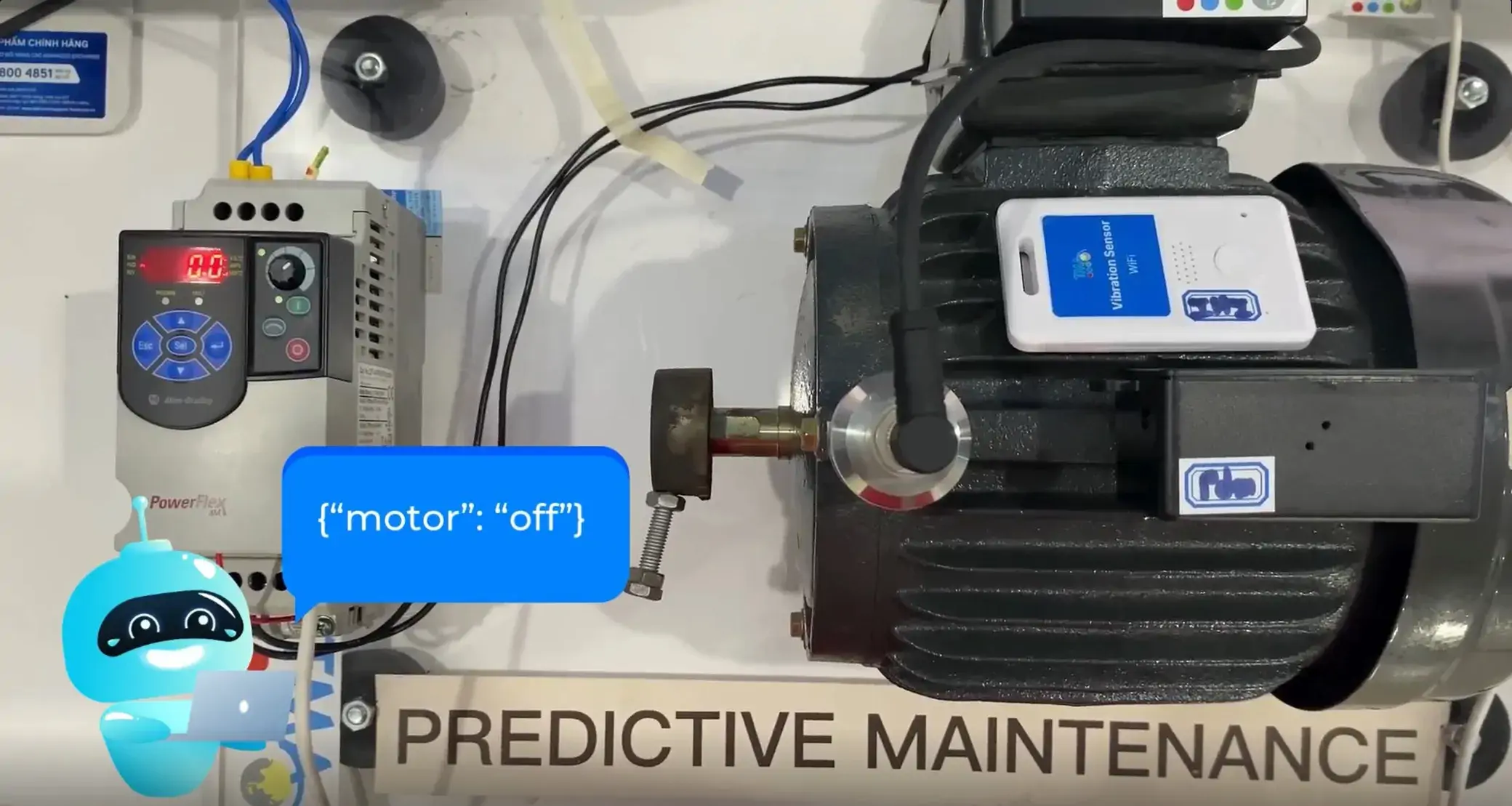

TMA’s Predictive Maintenance solution addresses these challenges by integrating Generative AI into the maintenance workflow:

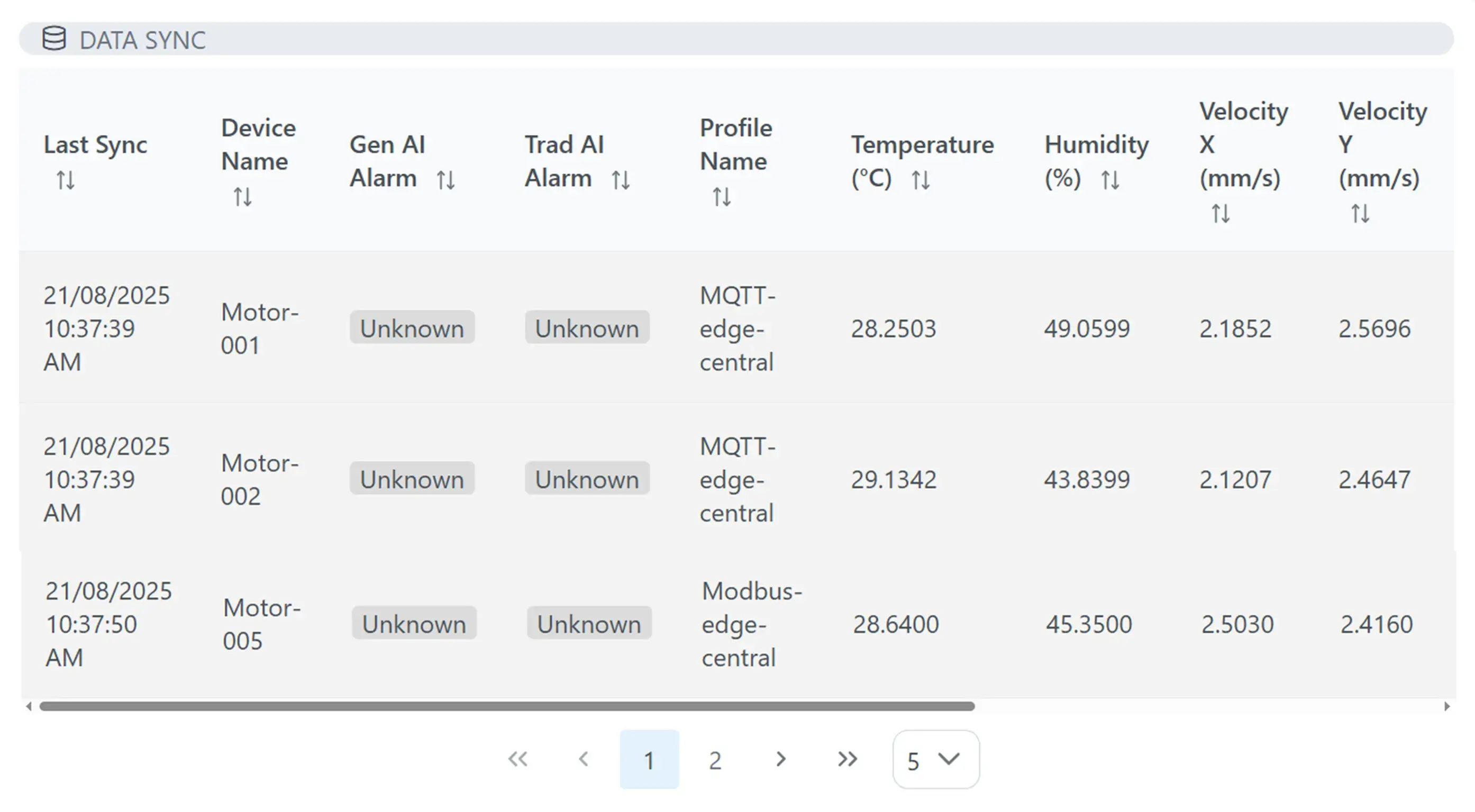

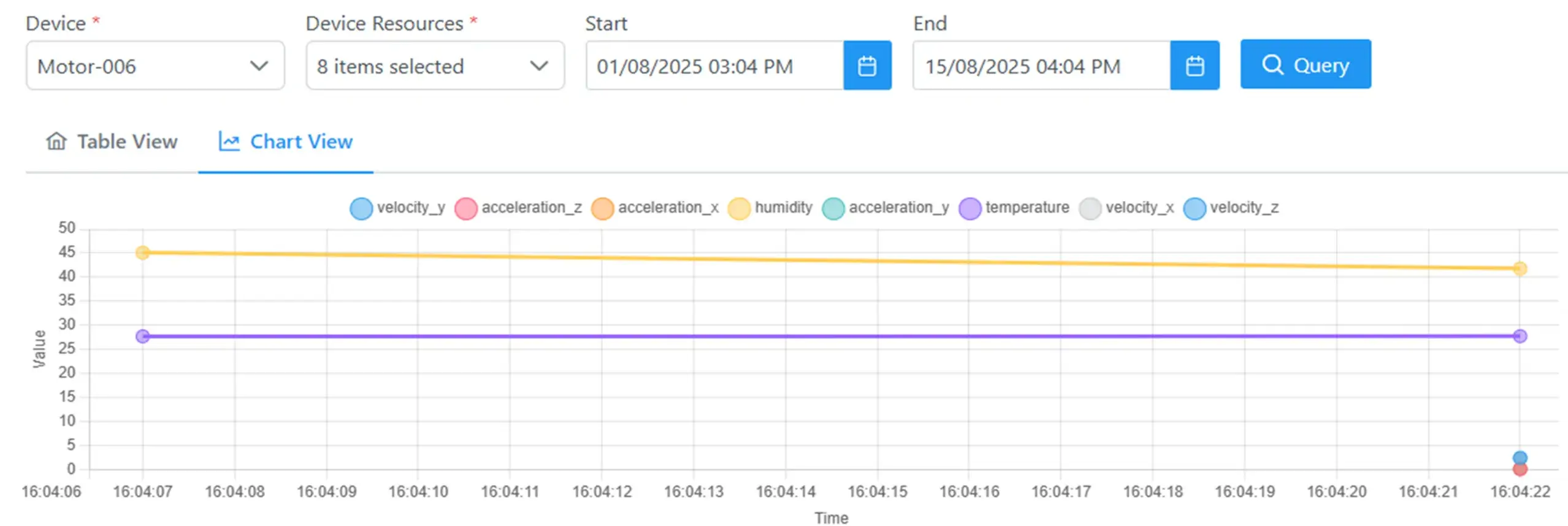

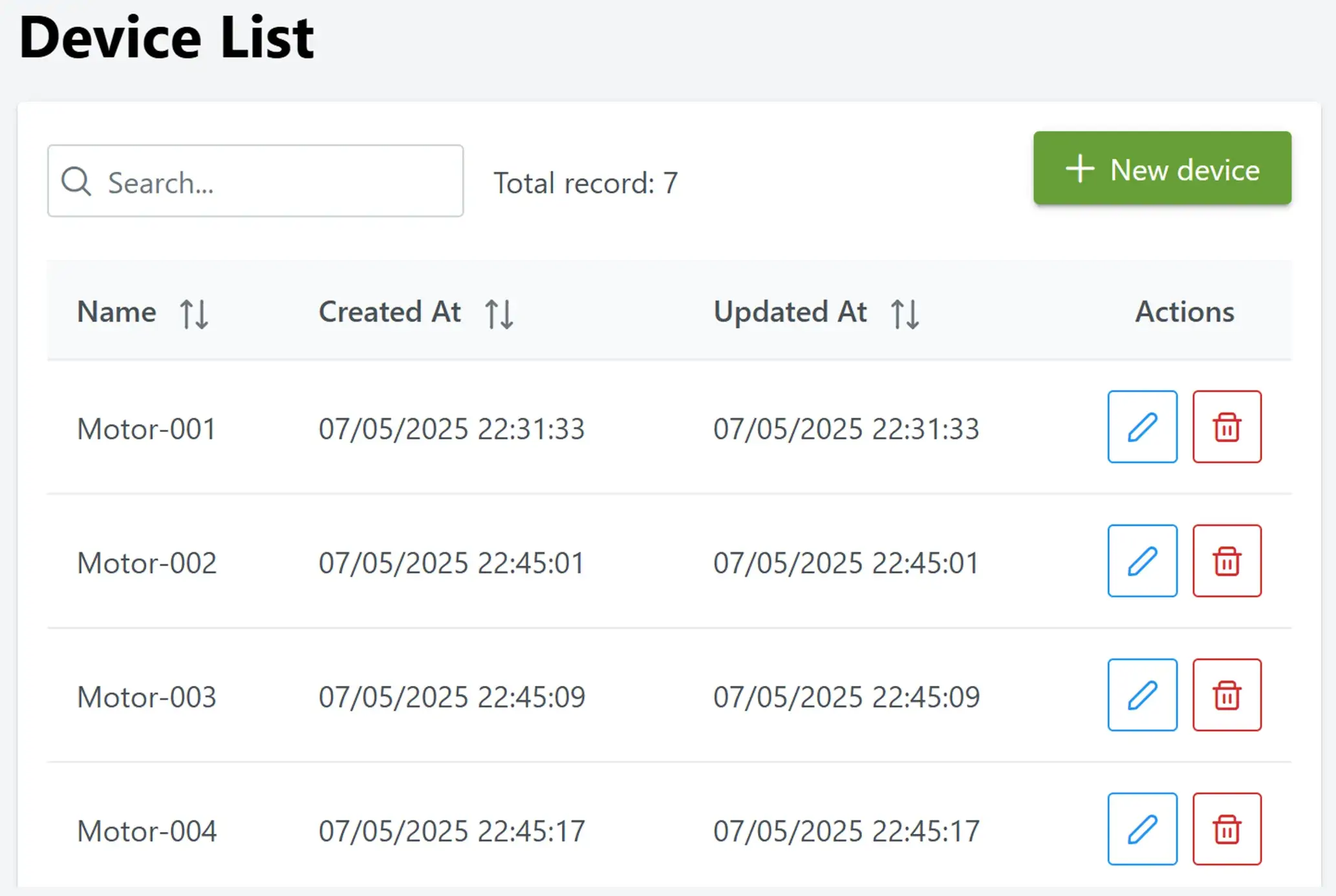

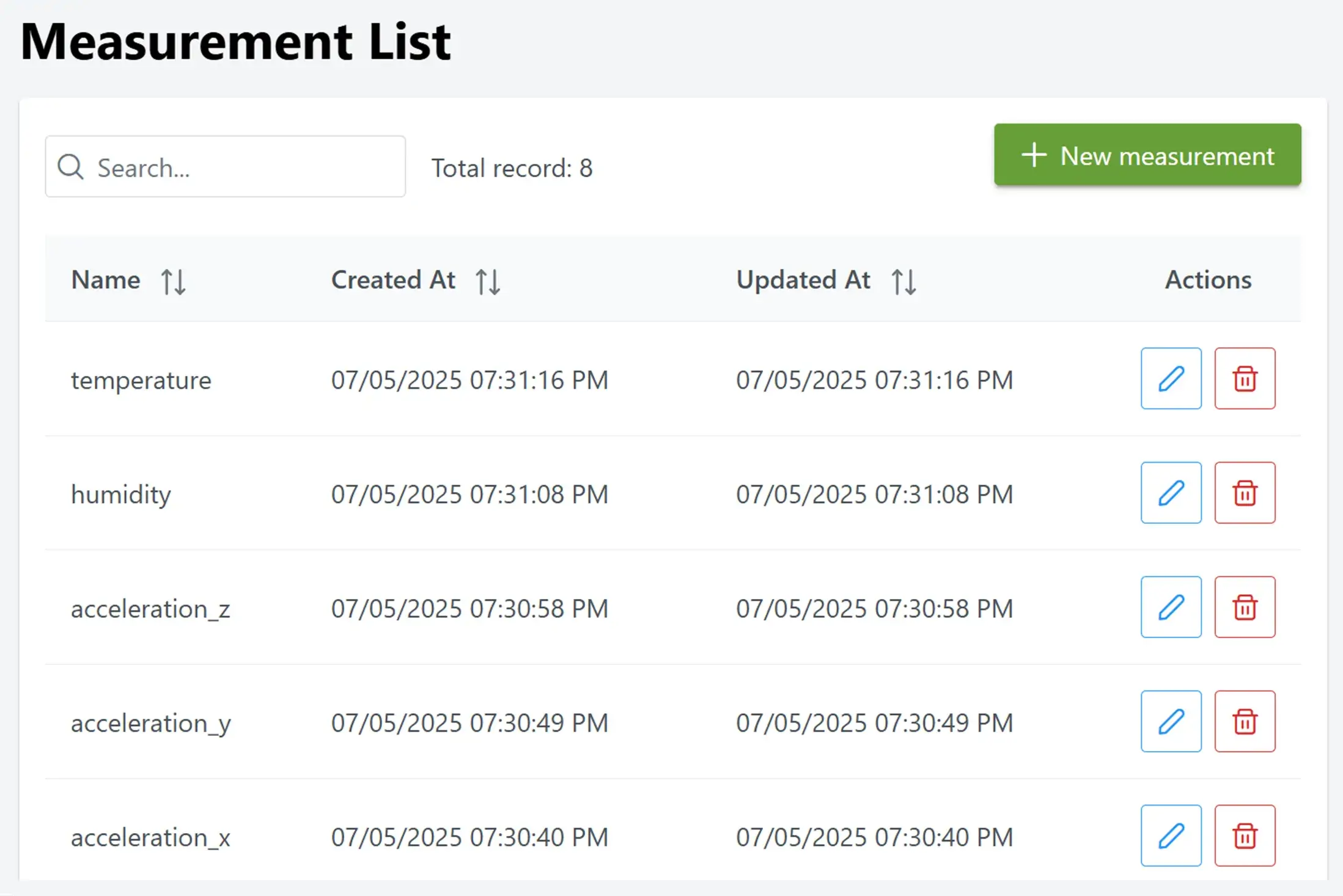

- AI log interpretation: Automatically processes complex machine logs and sensor data to detect early warning signs.

- Conversational insights: ChatGPT 4.0 generates human-readable maintenance summaries and recommendations tailored for frontline technicians.

- Smart scheduling: Enables proactive maintenance planning based on real-time equipment conditions, usage history, and AI predictions.