Defect Detection System by Sound

Leveraging advanced acoustic analysis, this solution identifies anomalies in real-time, optimizing manufacturing processes.

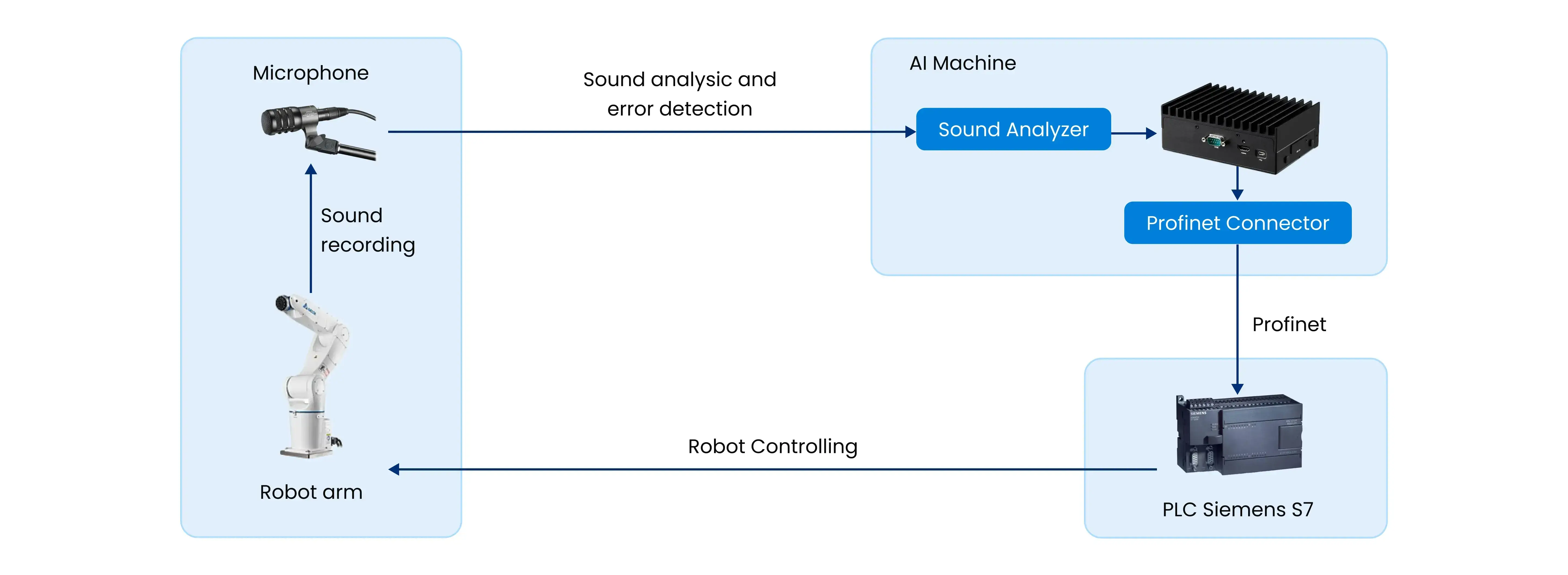

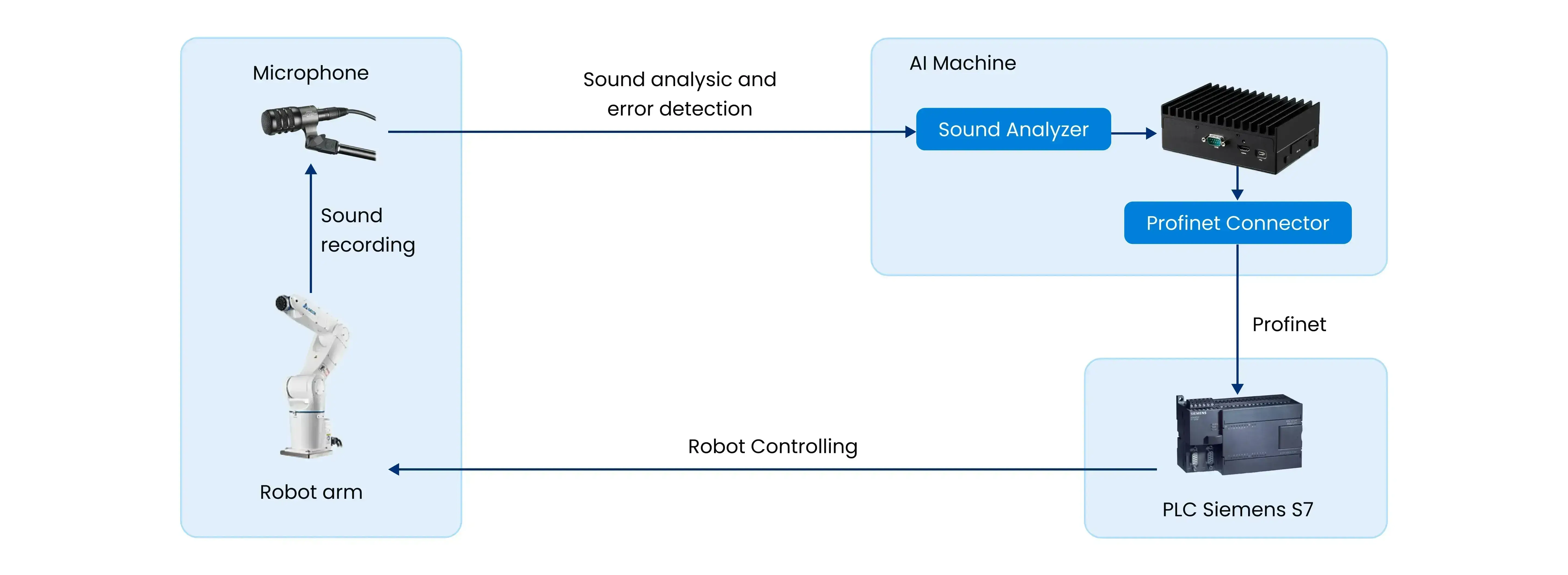

Capture high-fidelity acoustic data from machinery using precision microphones integrated with robotic arms

Employ advanced AI algorithms to analyze recorded sounds, instantly identifying abnormal patterns and potential defects

Facilitate automated responses and precise intervention by robotic arms, directly controlled by the system's error detection outputs

Elevates product quality through proactive, non-intrusive sound-based defect identification

Optimizes operational flow and minimizes downtime by quickly addressing emerging mechanical issues

A prominent Vietnamese manufacturer specializing in construction materials